What is a One-way Clutch?

What is a One-way Clutch?

A one-way clutch is a mechanical component that allows rotation in only one direction. Because it only rotates in one direction, it is used to prevent reverse rotation and to disconnect or transmit power. A familiar example is a bicycle. When you pedal, force is transmitted to the rear wheel, propelling the bike forward. However, if you stop pedaling or pedal backward, the rear wheel does not stop immediately but continues moving forward for a while. This occurs because a one-way clutch is installed on the rear wheel, blocking the force trying to rotate it backward. They are also used in the paper feed rollers of copiers. The roller only rotates in one direction, preventing the paper from moving backward. Thus, one-way clutches are vital components widely used in our daily lives, such as in bicycles and copiers.

This article explains what a one-way clutch is, the characteristics and benefits of the three main types, and their applications.

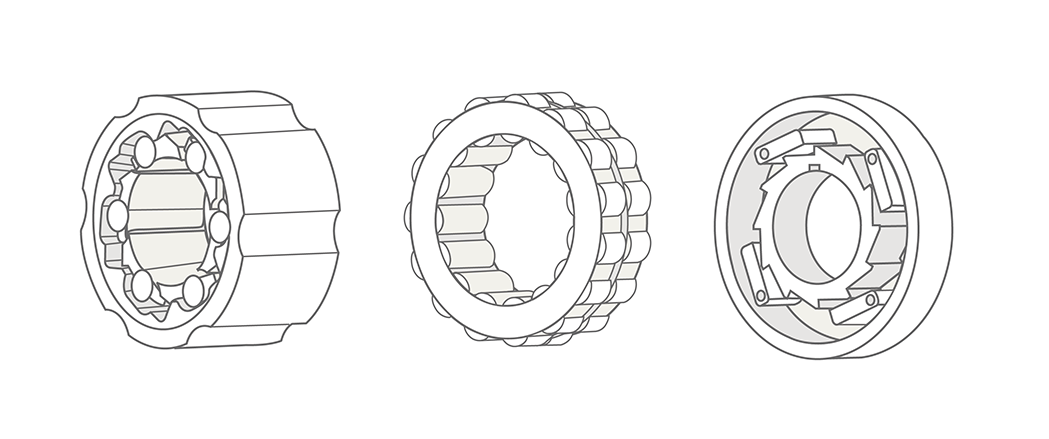

What is a roller type one-way clutch?

What is a roller type one-way clutch?

Structure and mechanism

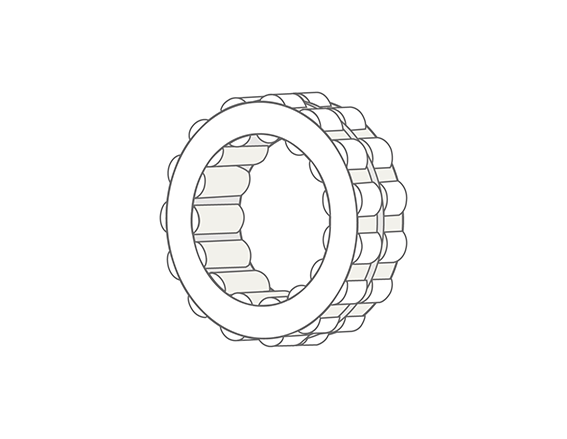

Roller type one-way clutches feature a precision cam profile machined onto either the inner diameter surface of the outer ring or the outer diameter surface of the inner ring. When rotating in one direction, the rollers (cylindrical rollers) in contact with this cam surface engage with the wedge and spring, enabling torque transmission. When rotating in the opposite direction, the rollers and spring disengage, allowing free rotation. TOK's one-way clutches fall under this roller type.

Furthermore, one-way clutches consisting solely of the clutch element use a housing made of drawn aluminum material, known as a shell type. On the other hand, TOK's one-way clutches are predominantly integrated types designed to mate with housings shaped like gears, cams, or pulleys. For some products (TCJ/TCK series), the clutch element can be used as a standalone component. For details, please see here.

Advantages

Its simple structure of rollers and springs facilitates miniaturization, enabling installation in limited spaces. Despite its compact size, it allows for a high-torque design. Its simple structure simplifies the manufacturing process, making it suitable for mass production and relatively low-cost manufacturing. Furthermore, it can operate at high rotational speeds. As a supplement, TOK's roller type one-way clutch uses sintered components impregnated with lubricating oil, making it a self-lubricating product.

Applications

Bait reels, copiers, cash handling machines, paper towel dispensers, etc.

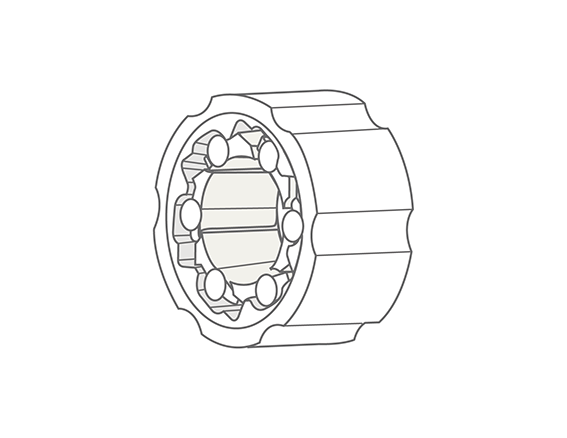

What is a sprag type one-way clutch?

What is a sprag type one-way clutch?

Structure and mechanism

The sprag type one-way clutch is a one-way clutch featuring numerous specially shaped cams called “sprags” arranged between an outer ring and an inner ring. This design disperses force and enables high torque transmission. When rotating in one direction, the sprags engage to transmit torque, and when rotating in the opposite direction, the sprags disengage, allowing free rotation. This type of one-way clutch is also known as a cam clutch.

Advantages

By arranging numerous sprags circumferentially, torque is distributed across a wide area rather than concentrating at a single point, enabling high torque transmission. Furthermore, springs maintain light contact between the sprags and the inner/outer rings at all times, minimizing engagement delay and allowing for quick response. Moreover, the angle required for the splugs to engage (backlash) can be made extremely small, making it suitable for applications requiring high-precision positioning. For reference, ratchet mechanisms require a certain angle for operation because they lock by engaging claws with teeth.

Applications

Bicycle rear wheels, automotive gearbox shifting, etc.

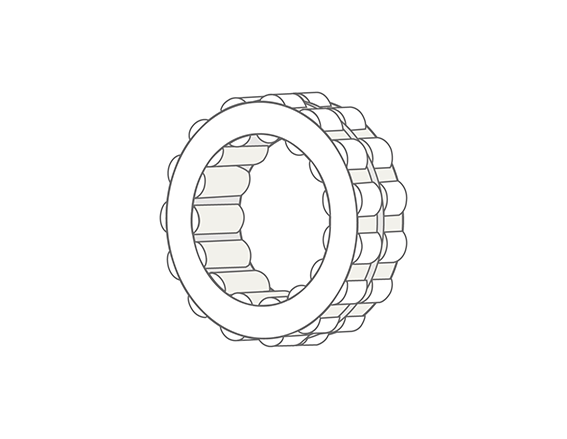

What is a ratchet type one-way clutch?

What is a ratchet type one-way clutch?

Structure and mechanism

The ratchet type one-way clutch employs a ratchet mechanism structure. It transmits rotation in one direction by engaging claws with mating components (ratchet teeth). When rotating in one direction, the claws disengage from the teeth, allowing smooth rotation without contact. When rotating in the opposite direction, the claws engage the teeth, locking the inner and outer rings to prevent reverse rotation. This is a simple structure. The difference between a one-way clutch and a ratchet is that a one-way clutch is a general term for mechanical elements that control the direction of power transmission, while a ratchet specifically refers to the mechanism that achieves this one-way clutch function.

Advantages

It requires no lubrication, making maintenance simple. Furthermore, during free rotation, the pawls disengage from the teeth, resulting in low friction resistance. Furthermore, its simple structure allows for high design flexibility and enables it to handle applications requiring transmission of very high torque.

Applications

Socket wrenches, ratchet spanners, bicycle pedals, automatic winding mechanisms in watches and music boxes, etc.

Summary of What is a One-way Clutch?

Summary of What is a One-way Clutch?

The one-way clutch is a crucial mechanical component that supports the operation of various machines and devices by allowing rotation in only one direction and preventing reverse rotation.

・Roller type one-way clutch: High rotational speed, long life, maintenance-free (for TOK products)

・Sprag type one-way clutch: High torque, high-precision positioning

・Ratchet type one-way clutch: Low friction, maintenance-free

This time, we introduced the three main types of one-way clutches. Please select products based on the advantages of each type. You can view the TOK roller type one-way clutches here.