About Us

| Company name | TOK, Inc. |

|---|---|

| Location: | 1-17-12, Azusawa, Itabashi, Tokyo, 174-8501, Japan |

| Founded: | June 1, 1925 |

| Established: | December 1, 1938 |

| President & CEO: | Keisuke Yoshikawa |

| TEL: | +81-50-1720-0482 |

| FAX: | +81-3-3558-7276 |

| The fiscal period: |

September |

| Dec. 1938 | Launched the Yoshikawa Seisakusho Co., Ltd with capital of 190.000 yen Azusawa, Itabashi-ku, Tokyo |

|---|---|

| Jan. 1946 | Changed company name to Yoshikawa Sangyo Co., Ltd. |

| Oct. 1965 | Developed and began highly successful sales of plastic bearings |

| Jun. 1972 |

Changed company name to TOK Bearing Co., Ltd. |

| Apr. 1974 |

Awarded as a model factory for small business rationalization by the Small and Medium Enterprise Organization(SMEO) |

| Mar. 1983 | Began sales of one-way clutches |

| Apr. 1986 | Merged TOK Seiko Co., Ltd Completed a new TOK Bearing factory in Yamanashi and commenced operations as the Yamanashi factory |

| Jul. 1989 | Began sales of torque limiters and TOK dampers |

| Jan. 1990 | Received a nationwide award from the Small and Medium Business Research Institute |

| Feb. 1990 | Awarded the 15th Invention Grand Prix for the invention of the one-way clutch |

| Nov. 1991 | Received and award for being and environmentally friendly enterprise from The Tokyo Chamber of Commerce of Industry |

| May. 1994 | Awarded as a model factory for small business rationalization for the consecutive 11 years by SMEO |

| Jul. 1995 | Established the Osaka office |

| Feb. 1996 | Established the Yamanashi office |

| Sep. 1996 | Established the Nagoya office |

| Oct. 1999 | Acquired ISO 9001 certification |

| Nov. 2000 | Acquired ISO 14001 certification |

| Oct. 2001 | Established TOK Industry(H.K.)Ltd. |

| Dec. 2000 | Began consignment production of one-way clutches in Yanbao, Shenzhen city |

| May. 2002 | Received the Emperor's royal visit to the Tokyo factory |

| Nov. 2002 | Established Shanghai TOK Precision Damper Bearing Co., Ltd. |

| Oct. 2004 | Established Shenzhen TOK Precision Component Moved to manufacturing base from Yanbao to Longgang |

| Jan. 2005 | Acquired ISO 9001 and 14001 certifications in Shenzhen TOK Precision Component |

| Feb. 2006 | Began sales of magnet type of torque limiters |

| May. 2006 | Awarded as one of 300 small and medium vital manufacturing companies in Japan by SMEO |

| Dec. 2006 | Japanese Prime Minister Abe toured the Tokyo factory |

| Jun. 2008 | Acquired ISO 9001 and 14001 certifications in Shanghai TOK Precision Damper Bearing Co., Ltd. |

| Dec. 2012 | Established the Product Development Center in Tokyo |

| Apr. 2013 | Established TOK PRECISION COMPONENT(SHENZHEN)CO., LTD |

| Feb. 2014 | Established a Representative Office in Dusseldorf, Germany |

| Dec. 2015 | Established TOK America, Inc. in Irvine California, USA |

| Apr. 2017 | TOK Bearing Co., Ltd. was renamed to TOK, Inc. for the 80th Anniversary |

| Feb. 2018 | Constructed new factory building in TOK’s Yamanashi factory |

| Mar. 2018 | TOK headquarters was relocated |

| Jun. 2023 | Established TOK Europe GmbH |

| Oct. 2025 | Awarded the Good Design Award, the SR100 |

| Dec. 2025 | Awarded the Invention Encouragement Award at the 2025 Kanto Regional Invention Awards, the Rotary Damper TD140. |

Awareness of environmental conservation is the most important objective for TOK. Our products: Bearings, One-way clutches, torque limiters, and rotary dampers are carefully monitored during the production process.

We put the utmost effort into conserving the environment and awareness of environmental issues because what we do to our planet affects us individually and collectively, now and for future generations.

1. We recognize the importance of environmental conservation and implement our production activities while considering their environmental impact.

2. We comply with all applicable requirements related to the environmental aspects of our company. Besides, we endeavor to protect the environment by setting voluntary standards and improving our standards towards having as little environmental impact as possible.

3. Each individual must construct and improve the environmental management system to improve performance and prevent further pollution of the environment.

4. When designing products, we implement an environmental management system to conserve and save energy and resources to reduce environmental impact.

5. Continuously setting environmental objectives and targets to improve the environment.

6. Each TOK individual is aware of these policies and strives to reach the goals of our environmental management system.

7. This policy is disclosed to the general public on our website and can be obtained at our reception desk.

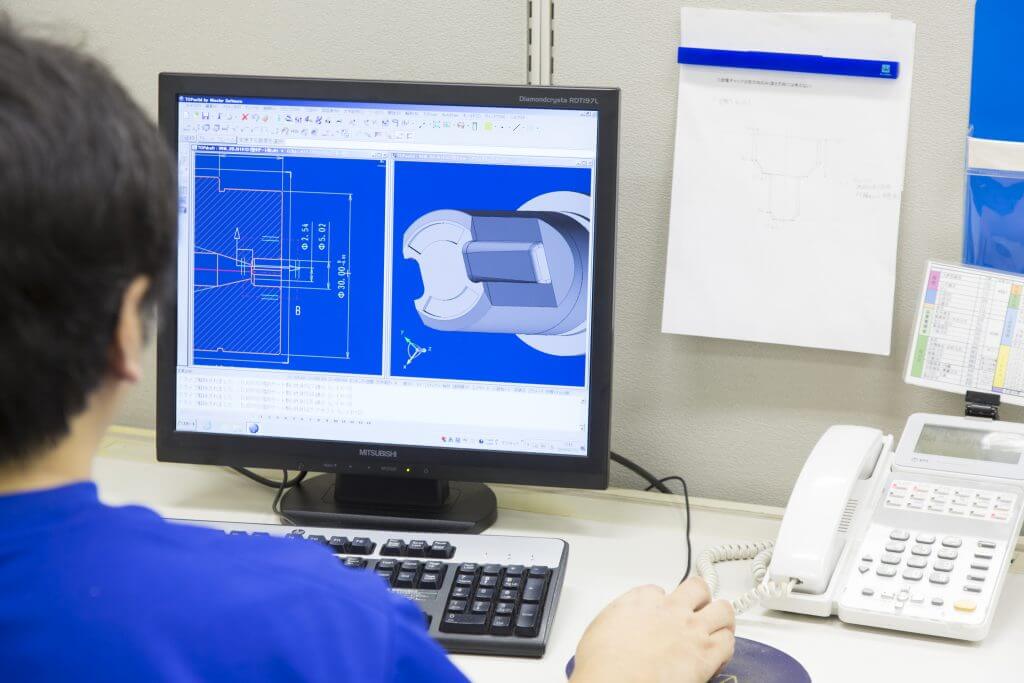

We will plan and propose new technologies and services characteristic of our organization. We test these new technologies using machines that focus on “control rotations” and ensure that the results meet your standards. Through our vast experience accumulated through past client interactions and inventions in a wide range of industries, we will work with you in ensuring you get the best possible design and performance at the lowest possible costs.

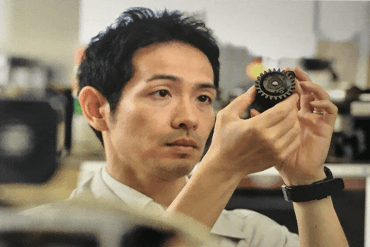

A product design begins by evaluating a trial production. We independently process components, resins, and metals used for trial productions. We keep our client’s requests in mind during these trial productions and try to ensure that we achieve your desired results.

At TOK, we take pride in our development structure and our belief in the concept of value analysis: making sure that our clients are getting the desired results at the lowest possible costs to them regarding material, design, and implementation. To stand on this belief of ours, we thoroughly perform evaluation tests for each product. To ensure our strict evaluation standards, we have developed our evaluation equipment independently. We use testing machines produced based on our expert experience to perform daily evaluations that guarantee superior performance for all our products.

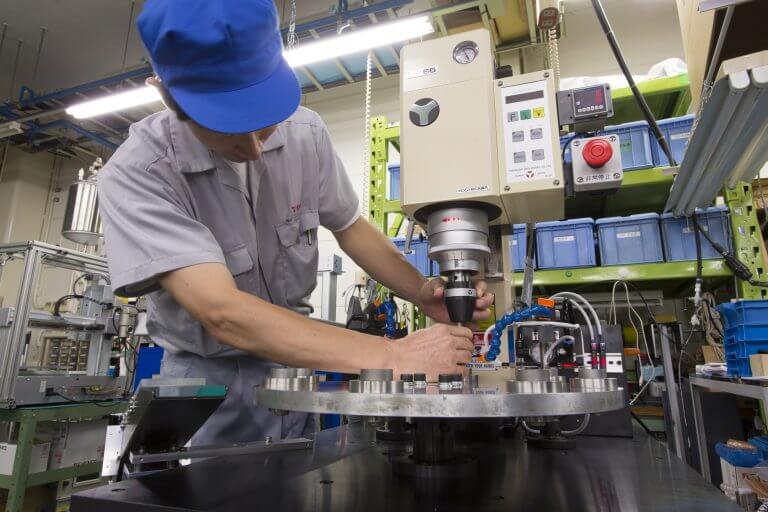

In manufacturing plastic products, building a mold is one of the most critical processes. To meet a wide variety of customer needs, TOK utilizes various machine tools to build high precision molds.

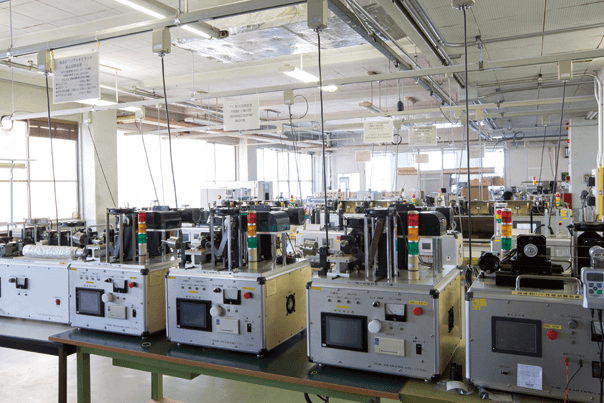

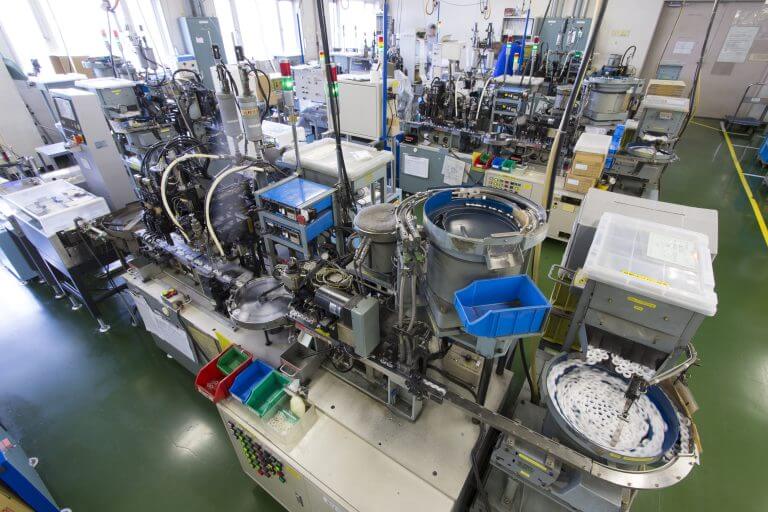

“Create an Environment That Produces Excellent Products” is one of our most central themes, and as such, TOK has continued to improve production facilities and production methods. We design and manufacture production equipment such as auto-assembly machines (for bearings and one-way clutches) built while conducting improvement. In-house designed production equipment and rigorous quality control structures have built a highly reliable and efficient production system. Besides, to build a global quality system, we have positioned the Yamanashi factory as the main production factory. The top standard of our production process, which from our overseas manufacturing subsidiaries, then applies that same top level of production and quality control to match Japan's.

Key Inspection Equipment

Gear rolling testers: Ogasawara Precision

Three-dimensional measuring machine: Mitutoyo

Image measuring machine: Mitutoyo

Laser measuring machine: Mitutoyo

Rockwell hardness testing machine: Mitutoyo

Roundness measuring machine: Tokyo Seimitsu

Shape measuring machine: Tokyo Seimitsu

Surface property measuring machine: Tokyo Seimitsu

Vickers hardness testing machine: Shimadzu

Load testing machine: Shimadzu

BEARING

TORQUE LIMITER

ROTARY DAMPER

ONE-WAY CLUTCH

SPEED REDUCER

PUBLIC

Cashing machine

Auditorium seat

Cash register

Vending machine

OFFICE

Copying machine

Printer

Cabinet

Ceiling fan

INDUSTRY

Electric driver

Conveyor belt

Etching machine

Molding machine

DAILY LIFE

Refrigerator

Toilet seat

Garbage can

Sliding door

LABORATORY

Medical equipment

Hemanalysis device

Chemical cleaning device

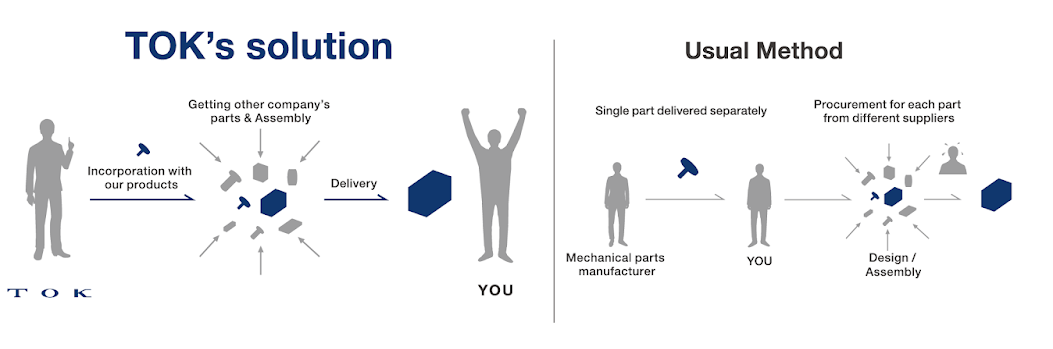

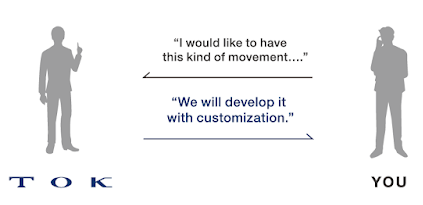

We are doing customized development tailored to customer’s needs.

We will provide the mechanisms that customers need on a case basis.

We are developing power control mechanisms and parts that improve the customers' products.