What are plastic bearings used for?

What are plastic bearings used for?

Plastic bearings are used in a wide variety of applications such as cabinets, desks, office automation equipment, money machines, and even equipment for handling chemicals. Why are plastic bearings used in so many fields? You might think that metal bearings are more precise and easier to use. The reason is that the characteristics of plastic bearings offer many advantages over metal bearings.

In this article, we will introduce why plastic bearings are used and the applications that take advantage of their plastic characteristics.

Why are plastic bearings being used?

Why are plastic bearings being used?

There are 3 reasons to use plastic bearings instead of metal bearings.

Reason 1: Self-lubricating properties

Self-lubrication means that sliding properties are maintained without the need for lubricating oil. Because of this self-lubricating property, plastic bearings do not require lubricating oil to prevent seizure like metal bearings do, and there is no need to worry about contaminating the surrounding area with oil.

Reason 2: Quietness

While metal tends to produce a high-pitched, grating sound when rolling, the rolling sound of resin is low due to the viscoelasticity of resin, resulting in a relatively quiet and soft impression.

Reason 3: Lightweight

The density of polyacetal resin commonly used in plastic bearings is 1.42 [g/cm3], which is approximately 20% of the density of steel materials (7.84 [g/cm3]), so the use of plastic parts contributes to overall product weight reduction.

Plastic bearings applications

Plastic bearings applications

Based on the mentioned reasons for using plastic bearings, here are some applications of plastic bearings.

Application 1: Refrigerator, desk, and chest drawers

Plastic bearings are mounted in the vegetable and freezer drawers of refrigerators, with the plastic bearings at the back of the drawer and at the front of the unit traveling on rails. Refrigerator drawers hold a variety of foods, from lightweight to heavy foods. Plastic bearings are not necessary for light foods such as cheese and butter, but they are suitable for foods as heavy as vegetables, and for heavy foods such as frozen foods, insert molded plastic bearings are suitable. The construction of drawers of desks and chests is basically the same as that of drawers in refrigerators, using rails and bearings. Plastic bearings are used in the middle and lower drawers, which are relatively heavier than the upper drawers.

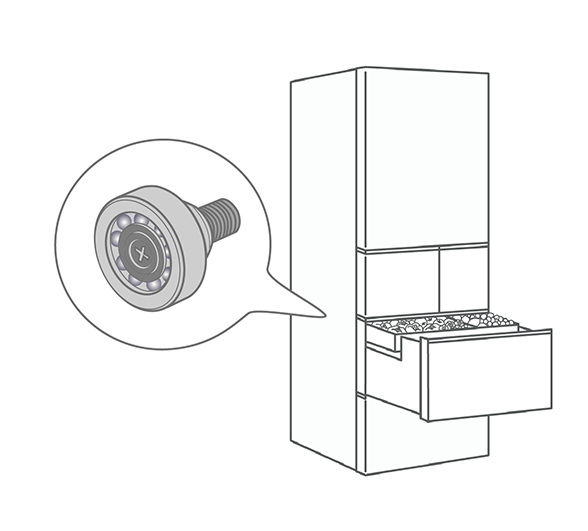

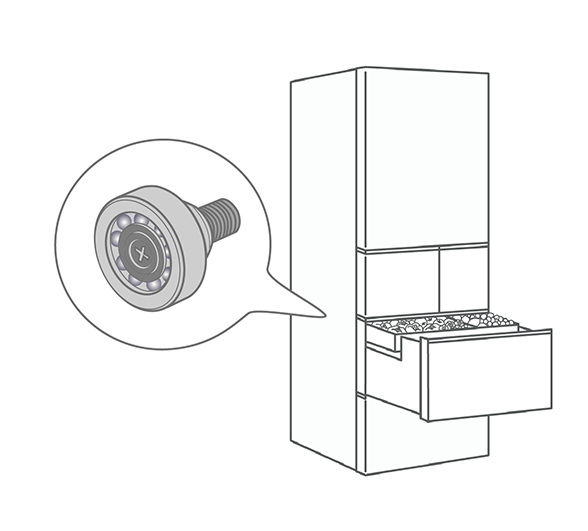

Application 2: Cabinets

Cabinets with plastic bearings can be pulled out to their full extent because they use a suspension mechanism, which incorporates another rail between the rails on the drawer side and the rails on the body side. In the past, filing cabinets were often used to store documents, so being able to pull out a full range of drawers was a big advantage to make it easier to store documents even at the back of the drawers. In addition, metal bearings were widely used in the past, but they were of excessive quality for cabinets and made a noticeable rolling noise. Since plastic bearings were introduced to the market, plastic bearings with optimum quality and quietness have become the mainstream. Recently, drawers with linear guide rails are often seen, but if a linear guide rail is damaged even slightly, the balls fall apart and it is very difficult to reassemble the whole system. With plastic bearings, repairs can be completed simply by replacing the plastic bearings, even if they are damaged.

Application 3: Sliding doors

In the past, most sliding doors had rails on the floor, but nowadays, with an emphasis on universal design, they do not have rails on the floor, but instead have a hanging wheel mounted on top for greater comfort. The rails on which the suspended door rollers run have a U-shaped with corners right angles or U-groove shaped running surface to prevent the plastic bearings from falling out, and the plastic bearings should be shaped to follow the shape of the running surface. For example, plastic bearings with a flat outer race shape are suitable for sliding doors with U-shaped with corners right angles rails and flat running surfaces, while plastic bearings with a round shaped outer race are suitable for U-groove shapes. Plastic parts can be molded into various shapes as long as the molds are made, so plastic bearings that fit the rail shape can be made in any way.

On the other hand, plastic bearings can also be used for sliding doors that have long been installed with dome shaped rails on the floor, such as the storage drawers. For dome shaped rails, U-groove shaped plastic bearings that follow the rails are suitable. Please click here to see the shapes of TOK's plastic bearings.

Application 4: High-speed scanner (OCR)

TOK's general plastic bearings, DR series bearings, may be charged with static electricity due to the insulating properties of resin, but ER series bearings are conductive and will not be charged with static electricity. This is because the plastic bearing materials such as outer race, retainer, and grease contain conductive materials. When paper is conveyed at high speeds, friction generates static electricity, and the plastic bearings absorb the paper dust that is blown into the air by the static electricity, which may cause problems in paper feeding due to poor rotation. To solve this problem, ER series bearings, which can conduct electricity, are used to conduct the static electricity that causes adsorption to the traveling rail side, thereby suppressing charging.

Application 5: Sliding bathing systems

Sliding bathing systems are used when a person in need of nursing care takes a bath. The person requiring care can take a bath while lying on a stretcher, and the stretcher is carried by a gurney, the stretcher is slid over the bathtub, and the bathtub is raised. In this device, water-resistant plastic bearings are used in the part where the stretcher slides. The water-resistant plastic bearings, which are rust-resistant even in wet or humid environments, use plastic for the outer race and retainer, and rust-resistant stainless steel for the inner race and ball. Conventional plastic bearings are injected with grease, but this time grease is not used because of the bathtub.

Summary of What are plastic bearings used for?

Summary of What are plastic bearings used for?

In this article, we have introduced 3 characteristics of plastic bearings and 5 examples of applications. With their superior characteristics not found in metal bearings, such as self-lubrication, quietness, and light weight, plastic bearings are ideal for applications such as refrigerators, desk drawers, cabinets, sliding doors, high-speed scanners, and sliding bathing systems. For other applications, resin materials can be changed to provide chemical resistance and heat resistance. More detailed information is available in the catalog, and please feel free to contact us if you have any questions.