What is a Plastic Bearing?

What is a Plastic Bearing?

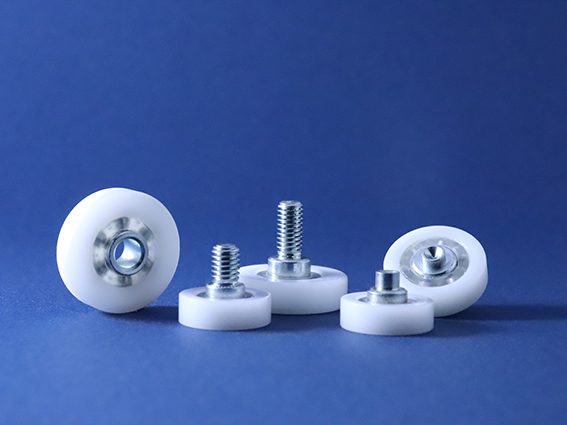

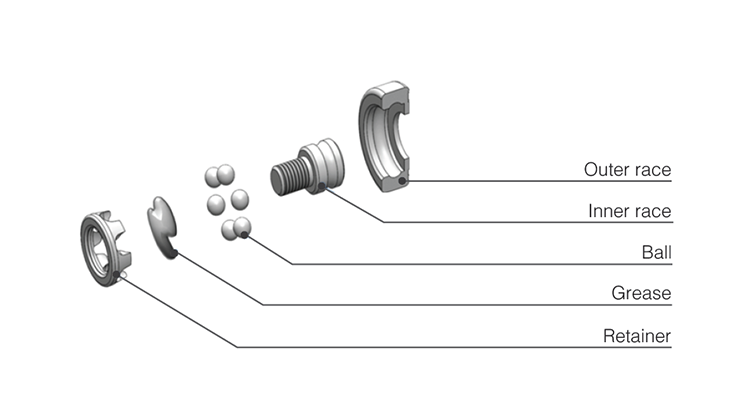

A plastic bearing is a type of bearing where one or more components, like the outer races or retainers, are made from plastic materials. It's designed for applications where traditional metal bearings are unsuitable. The features of general plastic bearings are that plastic materials are often used for an outer race, which is a bearing ring, and a retainer that holds rolling elements (balls). Bearings are used to make sliding doors and other devices lighter and easier to move smoothly, but do you know what differences and features plastic bearings have compared to metal bearings? Plastic bearings have many advantages that metal bearings do not.

In this article, we explain what a plastic bearing is and the advantages and disadvantages of using them.

What is a plastic bearing?

What is a plastic bearing?

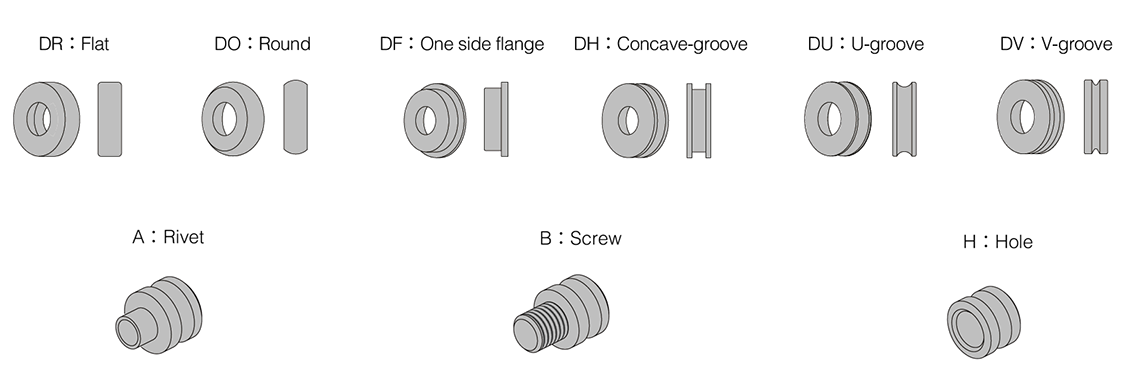

Plastic bearings are available with all parts made of plastic or only some parts made of plastic. Most plastic bearings that TOK manufactures as standard products consist of a plastic outer race and retainer, a metal inner race and ball, and grease. While general metal bearings are composed of metal parts and the outer circumference of the outer race is often flat, plastic bearings are unique because you can choose them in a wide range of shapes. Another feature is that the material can be changed to suit the application, such as using a bearing made of a chemical resistant material for environments where metal bearings are prone to corrosion.

What are the advantages of using plastic bearings?

What are the advantages of using plastic bearings?

The main advantages of using plastic bearings are as follows.

・ Flexible option according to the application

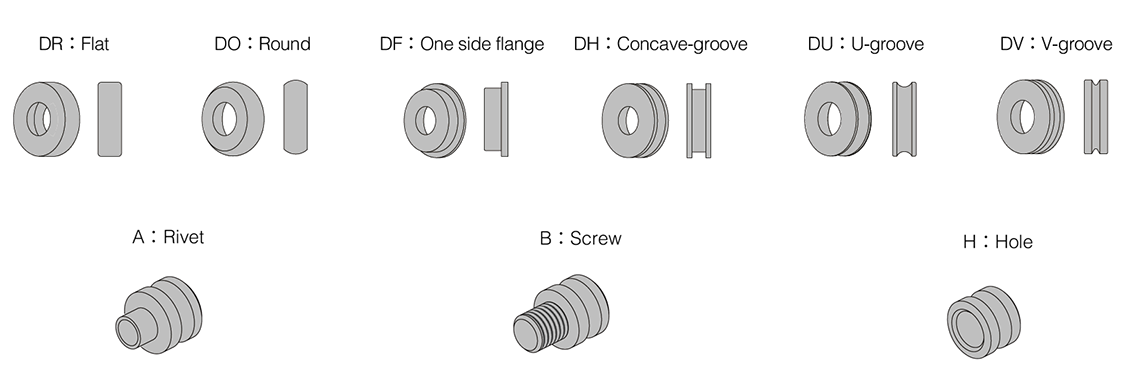

Plastic bearings can be manufactured in any desired size and shape by molding or cutting, taking advantage of the characteristics of plastic. TOK supplies six types of outer race shapes and three types of inner races as standard products. For example, when a bearing is used on a V-groove rail, we recommend the outer race with DO shape.

You can also choose the material to match the environment in which bearings are used. When used in chemical solutions, we recommend bearings made of PE or PEEK materials, which have chemical resistance, because they are more resistant to corrosion than metals. For low temperature environments, you can use bearings with clearances appropriate for the environment, designed for the linear shrinkage of each component.

Furthermore, if rotational accuracy and durability performance are required, you should select plastic wound bearings with inserted molded steel bearings to obtain both the advantages of plastic and metal.

Since suitable materials are different depending on the conditions of use, you need to confirm the actual product with a prototype in case of a special environment.

TOK designs each part of the plastic bearing to be common, so you can flexibly customize them. Therefore, even if a product is not in our catalog, we can produce it with a short delivery time and at no cost by combining the desired parts.

・ Hard to damage the mating material

If the surface on which the bearing runs is a metal or other material that is harder than the plastic, the running surface is less likely to be scratched as the outer circumference of the bearing wears. In addition, resins such as POM used in TOK D series bearings are self-lubricating and are less likely to damage the mating material.

・ Silent running noise

When metal bearings run on metal rails, they collide with each other and generate loud noise, which may not be suitable for use in a quiet indoor environment. With plastic bearings, since the outer race is made of plastic, no loud noise is generated when the bearings collide with metal, thus enhancing the quietness of the product.

What are the disadvantages of using plastic bearings?

What are the disadvantages of using plastic bearings?

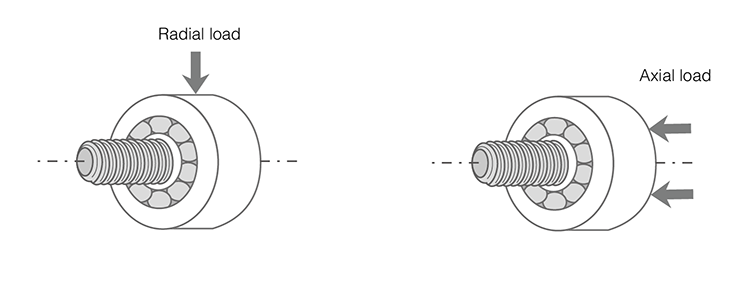

It is important to use plastic bearings in the proper direction of load. A load applied perpendicular to the bearing shaft is called radial load, and a load applied in the same direction as the shaft is called axial load.

It is necessary to use bearings suitable for each loading direction. If not used in the proper loading direction, durability may be affected, and leading to damage. In addition, plastic has a lower load capacity than metal, so it is necessary to avoid impact and excessive loading. When using plastic bearings, please carefully check the specifications of the product you are using.

Summary of What is a Plastic Bearing?

We manufacture and sell plastic bearings for various applications. We select a product according to the customer's application, and if it is not available in our standard products, we will propose recombination of parts or customized products.

We will design the product according to your desired performance, budget, and usage, so please feel free to contact us via this contact form.