Rotary Dampers

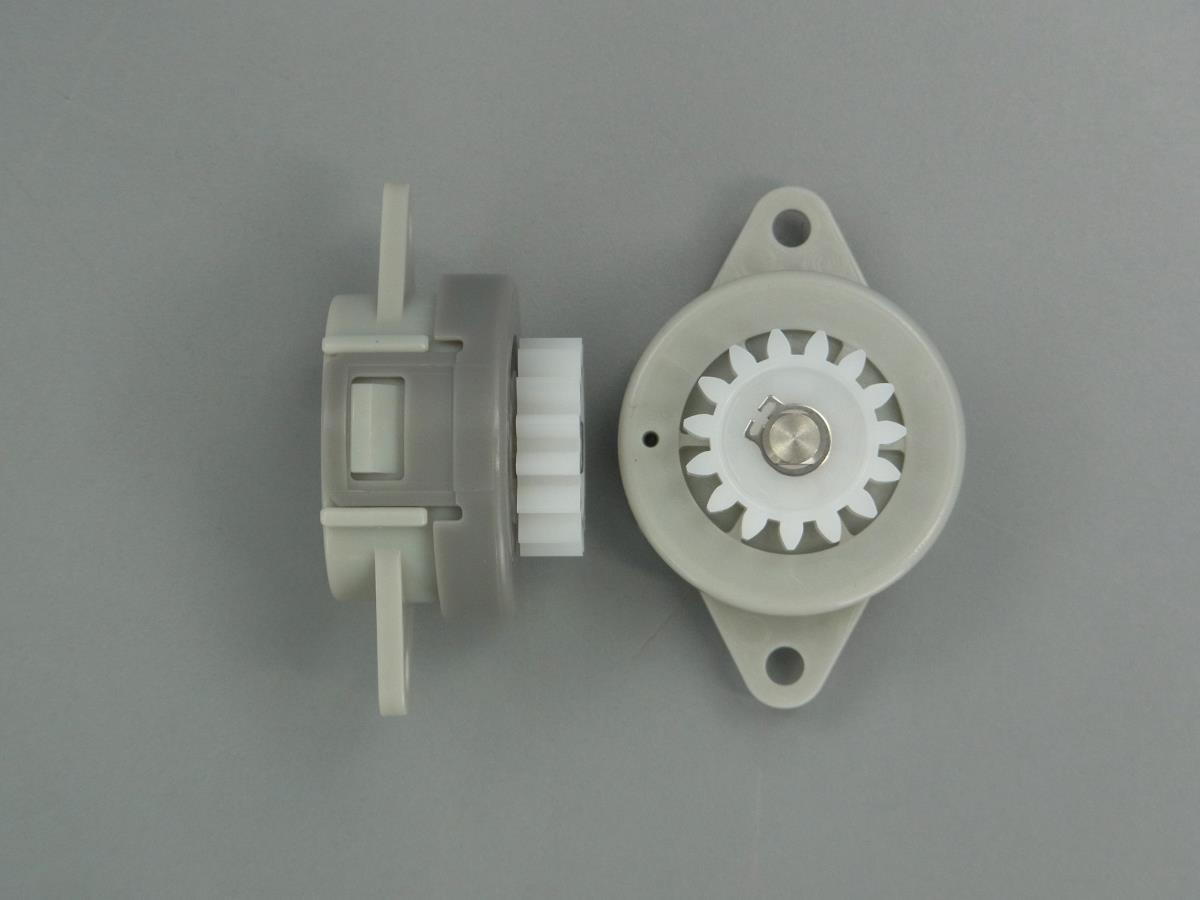

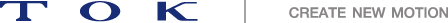

These are our proprietary rotary dampers. They are characterized by their ability to demonstrate high torque, despite being so compact. These are mechanical components that can meet demands such as ensuring safety, buffering, impact, and adding a high-end, luxurious feel to your product. Both finite and infinite angle types are available, depending on your needs.

This unique product was engineered by TOK, taking advantage of TOK’s wide array of technologies and systems.

TOK dampers are highly suitable where non-impact, noise-free, controlled motion is required. While torque is the primary consideration when specifying a TOK damper, our products cover a wide range of design specifications. Two types of standard dampers are available: rotary and uni-directional.

Please contact us to assist you in the design, engineering, and manufacturing of your specific damper application. Note: Please review the operational conditions stated in the TOK catalog when choosing and operating TOK products.

Rotary dampers provide a full range of motion where low noise and smooth motion is desired.

Applications

・ Sanitary: toilet seat & cover and shower door hinge

・ Furniture: office desk drawers, kitchen cabinets, and sliding doors

・ Home appliances: refrigerators and washer/dryers

・ Piano covers, vending machine flaps, air filter covers, and OA printers![]()

| Product Families | Damping Torque | Dimension |

|---|---|---|

| TD73 | 0.10 - 0.29 N・m | Φ11mm |

| TD75 |

0.10 - 0.29 N・m | Φ11mm |

| TD38 | 0.15 - 0.59 N・m | Φ22mm |

| TD27/28 | 0.49 - 1.96 N・m | Φ22mm |

| TD60 | 0.98 - 1.96 N・m | 11.9mm wide |

| TD56 | 1.47 - 2.94 N・m | Φ18mm |

| TD69 | 1.96 - 3.43 N・m | Φ20mm |

| TD22 | 2.45 - 3.92 N・m | Φ16.2mm |

| TD42 | 4.90 - 8.83 N・m | Φ40.2mm |

| TD89 | 3.0 - 10.0 N・m | 27mm wide |

| TD99 | 0.98 - 1.96 N・m | Φ18mm |

| TD100 | 0.98 - 2.94 N・m | Φ16mm |

| TD112 | 0.45 - 2.94 N・m | Φ18mm |

| TD118 | 1.5 - 3.5 N・m | Φ18mm |

| TD129 | 3.5 - 4.0 N・m | Φ16mm |

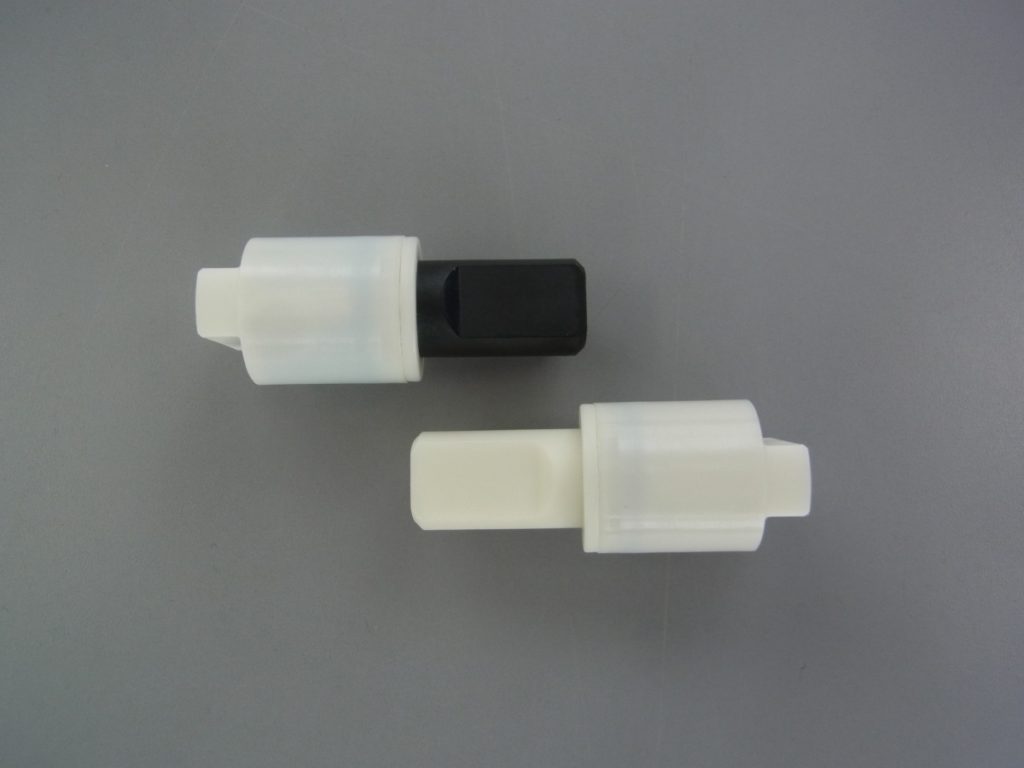

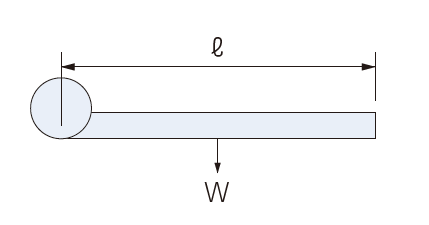

Calculating torque from lid size and weight

T(Nm) = W x 9.8 x (ℓ / 2)

T: Torque (Nm)

W: Weight (kg)

ℓ: Distance from fulcrum to tip (m)

*Converting weight in SI units and assuming that the center of gravity is at the center.

e.g.)

W: 2.0kg ℓ: 0.5m (50cm) Calculate the required torque in this case

T = 2.0 (kg) x 9.8 x (0.5 (m) / 2) = 4.90 (Nm)

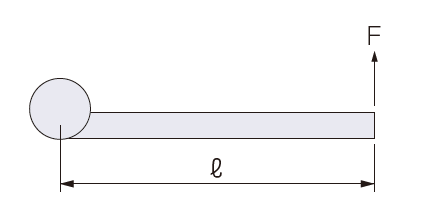

Calculating torque from lid size and lifting force

T(Nm) = F (maximum) x ℓ

T: Torque (Nm)

F: Lifting force at lid tip (N)

ℓ: Distance from fulcrum to tip (m)

*Using lid lifting force and distance from fulcrum to tip.

e.g.)

F: 2.0N ℓ: 0.5m (50cm) Calculate the required torque in this case

T = 2.0 × 0.5 = 1.0 (Nm)