What is the price of a one-way clutch? A clear explanation of price ranges by type and selection methods

What is the price of a one-way clutch? A clear explanation of price ranges by type and selection methods

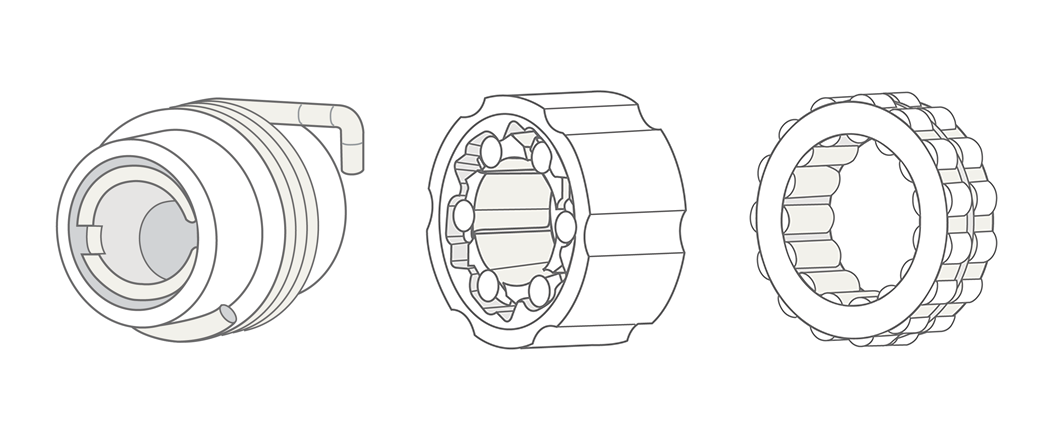

When selecting a one-way clutch, many people likely wonder, “What is the price of a one-way clutch?” and “What are the differences between types?” In reality, the price of a one-way clutch varies significantly based on structural differences, torque, size, durability, and other factors.

This article explains everything from the overall price range of one-way clutches to the differences between types and how to choose one.

Basic Price Trends for One-Way Clutches

Basic Price Trends for One-Way Clutches

One-way clutch prices tend to be lower for simpler designs and higher for more complex structures, larger sizes, and higher torque ratings. It is crucial to select the optimal type based on the required torque, size, and durability for your application.

One-way clutch prices tend to be lower for simpler designs and higher for more complex structures, larger sizes, and higher torque ratings. It is crucial to select the optimal type based on the required torque, size, and durability for your application.

Characteristics and Price Factors by One-Way Clutch Type

Characteristics and Price Factors by One-Way Clutch Type

One-way clutches vary significantly in structure and performance depending on the type.

Below, we clearly explain the key features and pricing differences for each major one-way clutch type.

Understanding the reasons behind each price point provides valuable insights for efficient, application-specific selection.

Spring Type Clutch | Simple Structure and Lowest Cost

Features an extremely simple structure, ideal for small-sized, low-torque applications.

While ideal for cost-priority designs, its low price makes it unsuitable for high-torque or long-life applications.

TCM Series | Standard Integrated Clutch

This type features a clutch element and housing integrated. It incorporates a clutch element with a sliding bearing, offering long life and maintenance-free operation. Its design accommodates larger shaft tolerances and keeps costs low.

TCK Series | Thin, Space-Saving Design

This type allows purchase of the clutch element alone without the housing.

It can be press-fit into gears, pulleys, levers, or cam-shaped plastic housings for use. Its thin design (narrow width) makes it ideal for space-constrained locations, but this requires higher part precision, increasing cost.

TCJ Series | High Torque & High Temperature Compatible

Like TCK Series, clutch elements can be purchased individually. This reinforced specification is compatible with high-temperature environments.

Consequently, it is more expensive than the TCK Series. It incorporates sintered bearings, eliminating the need for separate bearings and lubrication. It covers the high-torque range within TOK products, enabling powerful operation even in compact sizes.

Shell Type Clutch|Mid-to-High Price Range

A compact, high-torque one-way clutch.

Typically press-fit into a metal housing. While this requires a certain level of housing precision, it offers high design flexibility and a good balance between ease of use and performance. To deliver high torque, the cost is higher than previous one-way clutches.

Bearing-Integrated Shell Clutch | Convenience Focused

Integrates the bearing and clutch, reducing assembly steps.

Minimizes shaft runout for stable operation. The increased number of parts and machining processes result in a higher price compared to standard shell clutches.

Cam Clutch | High-Price Range

A high-performance type widely used in industrial machinery.

It features extremely high torque, high durability, and a long service life. Requiring precision machining, its high performance comes at a higher price, but it is indispensable in harsh environments.

Bearing-Integrated Cam Clutch | Top High-Price Range

Integrates the bearing and cam mechanism, achieving high precision and reliability.

While offering high maintainability, their design and machining costs are the highest, placing them in the upper high-price range among one-way clutches.

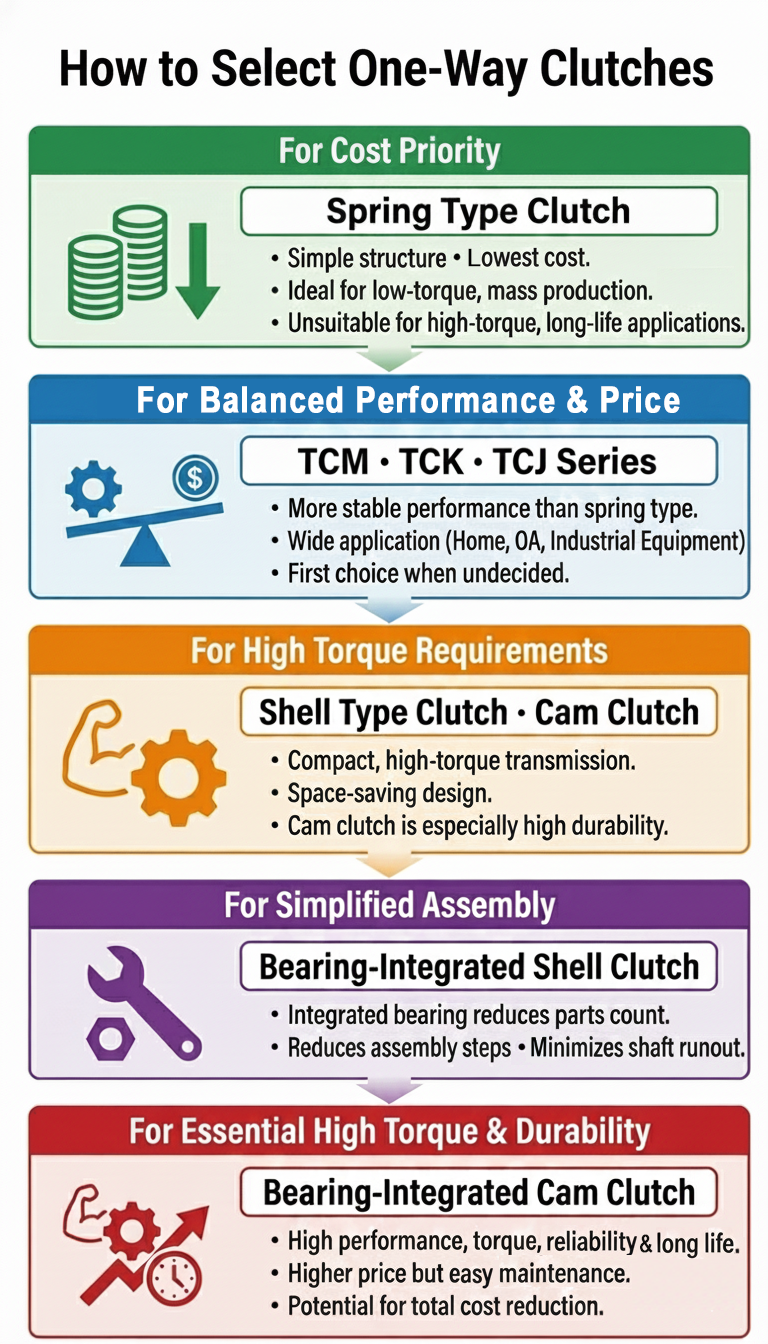

How to Select One-Way Clutches

How to Select One-Way Clutches

Based on the points discussed so far, we will now cover the key considerations for selecting a one-way clutch. Since there are many types of one-way clutches, choosing one that does not match the intended purpose or application can lead to excessive costs or insufficient performance. Understanding the following points will make it easier to select the optimal one-way clutch.

Summary of What is the price of a one-way clutch?

Summary of What is the price of a one-way clutch?

When selecting a one-way clutch based solely on price—whether high or low—it can lead to either over-specification driving up costs or underperformance. It is crucial to first determine the required torque, size, and durability before choosing the optimal one-way clutch.

For a detailed explanation of how one-way clutches work, please refer to our article “How does a One-Way Clutch Work?” We encourage you to read it as well.